Mastering Electric Vehicle Repair: Tools, Techniques, and Trends for Efficient Maintenance

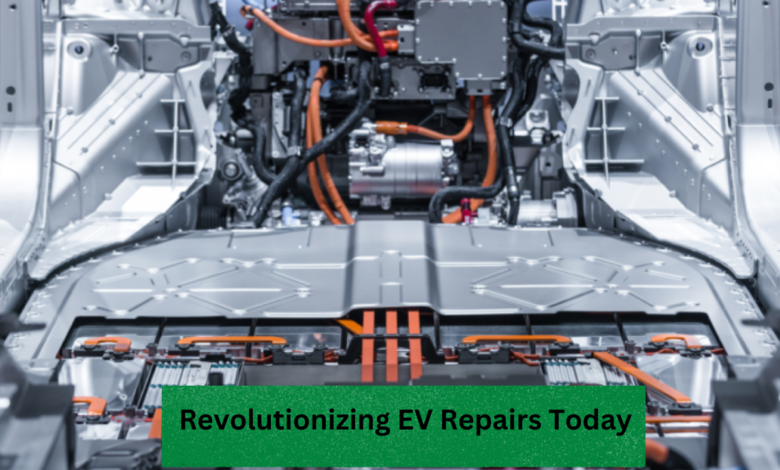

Electric Vehicle Repair-The rise of electric vehicles (EVs) represents a paradigm shift in the automotive industry. As EV adoption grows globally, the focus is shifting toward ensuring these vehicles are maintained and repaired effectively. Unlike traditional internal combustion engine (ICE) vehicles, EVs require specialized knowledge, tools, and skills for repair. This article explores the intricacies of electric vehicle repair, including common issues, repair processes, and the challenges faced by professionals in this evolving field.

Table of Contents

ToggleUnderstanding the Core Components of EVs

To comprehend EV repair, one must first understand the primary components that make them function:

- Battery Pack:

- The heart of the EV, made up of lithium-ion cells, provides power to the entire vehicle.

- Batteries are prone to degradation over time, losing capacity due to repeated charge cycles and exposure to extreme temperatures.

- Electric Motor:

- Converts electrical energy into mechanical energy to drive the wheels.

- Typically requires less maintenance compared to ICEs, but motor bearings or cooling systems can fail.

- Power Electronics Controller:

- Manages the distribution of electrical energy to various systems in the vehicle.

- Issues may arise due to software bugs or component wear.

- Charging System:

- Includes the onboard charger, connectors, and charge port.

- Problems can stem from damaged connectors or compatibility issues with charging stations.

- Thermal Management System:

- Ensures the battery, motor, and other components remain within optimal temperature ranges.

- Faulty pumps, leaks, or cooling fans can lead to overheating.

- Software and Sensors:

- EVs rely heavily on advanced software and sensors for efficient operation and safety.

- Software updates or sensor malfunctions can impact performance.

Common Issues in Electric Vehicles Repair

While EVs boast lower maintenance needs compared to ICE vehicles, they are not immune to problems. Here are some of the common issues encountered:

- Battery Degradation:

- Loss of range and charging efficiency over time.

- Requires diagnostic tests to assess battery health and, in extreme cases, replacement.

- Charging Port Issues:

- Damaged connectors or software glitches can impede charging.

- Solutions may involve replacing physical components or resetting systems.

- Motor Malfunctions:

- Unusual noises or reduced power output might indicate motor wear or cooling issues.

- Repairs often involve replacing bearings or inspecting the cooling system.

- Brake System Problems:

- Regenerative braking systems are unique to EVs and may require recalibration or component replacement.

- Software Failures:

- Faulty updates or corrupted data can lead to operational issues.

- Typically resolved with diagnostic tools and reinstallation of firmware.

Tools and Equipment for Electric Vehicle Repair

EV repair demands specialized tools to address their unique construction and systems. These include:

- Diagnostic Scanners:

- Used to access and interpret error codes in the vehicle’s system.

- Helps identify issues with sensors, software, and electronics.

- High-Voltage Insulation Tools:

- Essential for safely working on components like the battery pack and motor.

- Includes insulated gloves, tools, and multimeters.

- Battery Repair Kits:

- Tools for opening and diagnosing battery packs, including thermal cameras to detect hotspots.

- Lifting Equipment:

- Heavy-duty lifts to safely access components located beneath the vehicle.

- Thermal Management Equipment:

- Tools to check and maintain cooling systems, including leak detectors and flow meters.

Steps in Electric Vehicle Repair

The process of repairing an EV involves a structured approach to ensure safety and efficiency:

- Safety Precautions:

- Isolate the high-voltage system to prevent electric shocks.

- Use personal protective equipment (PPE), including gloves, goggles, and insulated clothing.

- Diagnostics:

- Use diagnostic tools to scan the vehicle for error codes.

- Assess the condition of key components, including the battery, motor, and power electronics.

- Component Repair or Replacement:

- Address the identified issue, whether it involves replacing a battery module, repairing the motor, or fixing software bugs.

- Testing:

- After repairs, test the vehicle to ensure proper functioning.

- Check for error codes and confirm the resolution of the issue.

- Documentation:

- Record the repairs performed, parts replaced, and any observations for future reference.

Challenges in Electric Vehicle Repair

- High Voltage Risks:

- EVs operate on high-voltage systems, posing a significant risk to untrained personnel.

- Limited Expertise:

- The rapid evolution of EV technology means many technicians are still learning the nuances of repair.

- Cost of Repairs:

- EV components, particularly batteries, are expensive to replace, often making repairs cost-prohibitive.

- Access to Parts:

- OEMs often restrict access to spare parts, making it difficult for independent garages to perform repairs.

- Software Complexity:

- Advanced software systems require regular updates and expertise in troubleshooting.

Training and Certification for EV Technicians

To meet the growing demand for Electric Vehicle Repair, technicians must undergo specialized training. Key certifications include:

- ASE EV Certification:

- Offers courses on EV systems and safety protocols.

- Manufacturer-Specific Training:

- Many automakers provide training programs tailored to their models, such as Tesla’s START program.

- High-Voltage Safety Training:

- Focuses on safely working with and repairing high-voltage systems.

- Battery Diagnostics Certification:

- Covers in-depth battery testing and repair techniques.

Emerging Trends in Electric Vehicle Repair

- Remote Diagnostics:

- Many EVs now offer over-the-air (OTA) updates and diagnostics, reducing the need for physical repairs.

- Modular Repairs:

- Battery packs and other components are increasingly designed to allow for modular replacements, minimizing costs.

- 3D Printing:

- Emerging as a solution for creating custom parts that may not be readily available.

- Artificial Intelligence:

- AI-powered tools are helping technicians diagnose and repair issues more accurately.

The Future of EV Repair

As EV adoption increases, the repair ecosystem is expected to evolve in the following ways:

- Widespread Training:

- A surge in EV-specific training programs will lead to a more skilled workforce.

- Collaboration Between OEMs and Independent Repair Shops:

- Automakers may partner with independent garages to widen the network of repair facilities.

- Focus on Sustainability:

- Efforts to recycle and refurbish batteries and other components will gain prominence.

- Standardization:

- As the industry matures, repair processes and tools are likely to become more standardized.

Conclusion

Electric vehicle repair is an evolving field that presents both challenges and opportunities. As the world transitions to sustainable transportation, the repair industry must adapt to the unique demands of EVs. By investing in training, embracing advanced tools, and focusing on innovation, the industry can ensure that EV owners receive the support they need to keep their vehicles running smoothly.